Reliable power distribution depends heavily on proper maintenance of critical protection equipment. In low-voltage electrical systems, routine inspection and testing are essential to prevent unexpected failures and ensure operational safety. A well-maintained Air Circuit Breaker (ACB) plays a key role in protecting main circuits by interrupting fault currents and maintaining system stability over long service periods.

1.Importance of Regular Maintenance for Power System Reliability

Regular maintenance helps reduce the risk of unplanned outages and costly downtime. Over time, electrical and mechanical components are subject to wear, environmental contamination, and thermal stress. Proactive maintenance programs allow potential issues to be identified early, extending equipment lifespan and ensuring consistent protection performance in commercial and industrial power systems.

2.Routine Inspection Procedures for Air Circuit Breakers

Routine inspections should include visual checks of insulation components, arc chutes, and operating mechanisms. Mechanical parts must be examined for smooth movement and correct alignment, while electrical connections should be checked for looseness or signs of overheating. Cleanliness is also critical, as dust and debris can negatively affect insulation and interrupting performance.

3.Functional Testing Methods and Performance Verification

Functional testing verifies that protection mechanisms operate correctly under simulated conditions. This includes mechanical operation tests, trip function verification, and response-time evaluation. Testing ensures that the Air Circuit Breaker (ACB) can respond accurately to overloads or short-circuit conditions and coordinate properly with other protective devices in the system.

4.Common Maintenance Issues and Troubleshooting Strategies

Common issues include contact erosion, mechanical wear, and improper tripping behavior. These problems may result from frequent switching operations, high fault levels, or insufficient maintenance intervals. Addressing such issues promptly through adjustment, repair, or component replacement helps restore normal operation and prevents more serious system faults.

5.Safety Precautions and Documentation During ACB Maintenance

Safety is a top priority during maintenance activities. Proper lockout and tagout procedures must be followed to isolate power sources before inspection or testing. Maintenance records, test results, and inspection reports should be carefully documented to support compliance with safety standards and provide a clear maintenance history. Consistent documentation also helps optimize future maintenance planning for the Air Circuit Breaker (ACB).

Conclusion

Effective maintenance and testing are essential for ensuring reliable performance of low-voltage power protection equipment. By implementing structured inspection routines, functional testing, and proper documentation practices, facilities can significantly enhance system reliability and safety. A disciplined maintenance approach ultimately supports long-term operational continuity and electrical system resilience.

FAQ

Q1: Why is regular maintenance important for main circuit protection devices?

Regular maintenance helps prevent unexpected failures, extends equipment lifespan, and ensures reliable fault protection.

Q2: How often should functional testing be performed?

Testing intervals depend on operating conditions and applicable standards, but periodic testing is generally recommended.

Q3: What are common signs that maintenance is required?

Unusual noises, visible wear, overheating marks, or irregular tripping behavior indicate the need for inspection.

Q4: Is documentation really necessary for maintenance work?

Yes. Proper records support safety compliance, audits, and long-term maintenance planning.

Q5: Can preventive maintenance reduce downtime?

Absolutely. Identifying issues early helps avoid unexpected outages and costly repairs.

References

-

IEC 60947-2: Low-voltage switchgear and controlgear – Circuit breakers

-

IEEE Recommended Practice for Maintenance of Electrical Power Equipment

-

NFPA 70B: Recommended Practice for Electrical Equipment Maintenance

-

Schneider Electric & ABB Technical Guides on Low-Voltage Power Distribution

PC ATS YECT1-2000G

PC ATS YECT1-2000G PC ATS YES2-63~250GN1

PC ATS YES2-63~250GN1 Solenoid-type ATS YES1-32~125N

Solenoid-type ATS YES1-32~125N Solenoid-type ATS YES1-250~630N/NT

Solenoid-type ATS YES1-250~630N/NT Solenoid-type ATS YES1-32~125NA

Solenoid-type ATS YES1-32~125NA Solenoid-type ATS YES1-63~630SN

Solenoid-type ATS YES1-63~630SN Solenoid-type ATS YES1-1250~4000SN

Solenoid-type ATS YES1-1250~4000SN Solenoid-type ATS YES1-250~630NA/NAT

Solenoid-type ATS YES1-250~630NA/NAT Solenoid-type ATS YES1-63NJT

Solenoid-type ATS YES1-63NJT PC ATS YES1-100~1600GN1/GN/GNF

PC ATS YES1-100~1600GN1/GN/GNF PC ATS YES1-2000~3200GN/GNF

PC ATS YES1-2000~3200GN/GNF PC ATS YES1-100~3200GA1/GA

PC ATS YES1-100~3200GA1/GA Solenoid-type ATS YES1-63~630SA

Solenoid-type ATS YES1-63~630SA Solenoid-type ATS YES1-63~630L/LA

Solenoid-type ATS YES1-63~630L/LA Solenoid-type ATS YES1-63~630LA3

Solenoid-type ATS YES1-63~630LA3 Solenoid-type ATS YES1-63MA

Solenoid-type ATS YES1-63MA PC ATS YES1-630~1600M

PC ATS YES1-630~1600M PC ATS YES1-3200Q

PC ATS YES1-3200Q Solenoid-type ATS YES1-4000~6300Q

Solenoid-type ATS YES1-4000~6300Q CB ATS YEQ1-63J

CB ATS YEQ1-63J CB ATS YEQ2Y-63

CB ATS YEQ2Y-63 CB ATS YEQ3-63W1

CB ATS YEQ3-63W1 CB ATS YEQ3-125~630W1

CB ATS YEQ3-125~630W1 ATS controller Y-700

ATS controller Y-700 ATS Controller Y-700N

ATS Controller Y-700N ATS Controller Y-701B

ATS Controller Y-701B ATS Controller Y-703N

ATS Controller Y-703N ATS Controller Y-800

ATS Controller Y-800 ATS Controller W2/W3 Series

ATS Controller W2/W3 Series ATS switch Cabinet floor-to-ceiling

ATS switch Cabinet floor-to-ceiling ATS switch cabinet

ATS switch cabinet JXF-225A power Cbinet

JXF-225A power Cbinet JXF-800A power Cbinet

JXF-800A power Cbinet YEM3-125~800 Plastic Shell Type MCCB

YEM3-125~800 Plastic Shell Type MCCB YEM3L-125~630 Leakage Type MCCB

YEM3L-125~630 Leakage Type MCCB YEM3Z-125~800 Adjustable Type MCCB

YEM3Z-125~800 Adjustable Type MCCB YEM1-63~1250 Plastic Shell Type MCCB

YEM1-63~1250 Plastic Shell Type MCCB YEM1E-100~800 Electronic Type MCCB

YEM1E-100~800 Electronic Type MCCB YEM1L-100~630 Leakage Type MCCB

YEM1L-100~630 Leakage Type MCCB Miniature circuit breaker YEMA2-6~100

Miniature circuit breaker YEMA2-6~100 Miniature circuit breaker YEB1-3~63

Miniature circuit breaker YEB1-3~63 Miniature circuit breaker YEB1LE-3~63

Miniature circuit breaker YEB1LE-3~63 Miniature circuit breaker YEPN-3~32

Miniature circuit breaker YEPN-3~32 Miniature circuit breaker YEPNLE-3~32

Miniature circuit breaker YEPNLE-3~32 Miniature circuit breaker YENC-63~125

Miniature circuit breaker YENC-63~125 Air Circuit Breaker YEW1-2000~6300

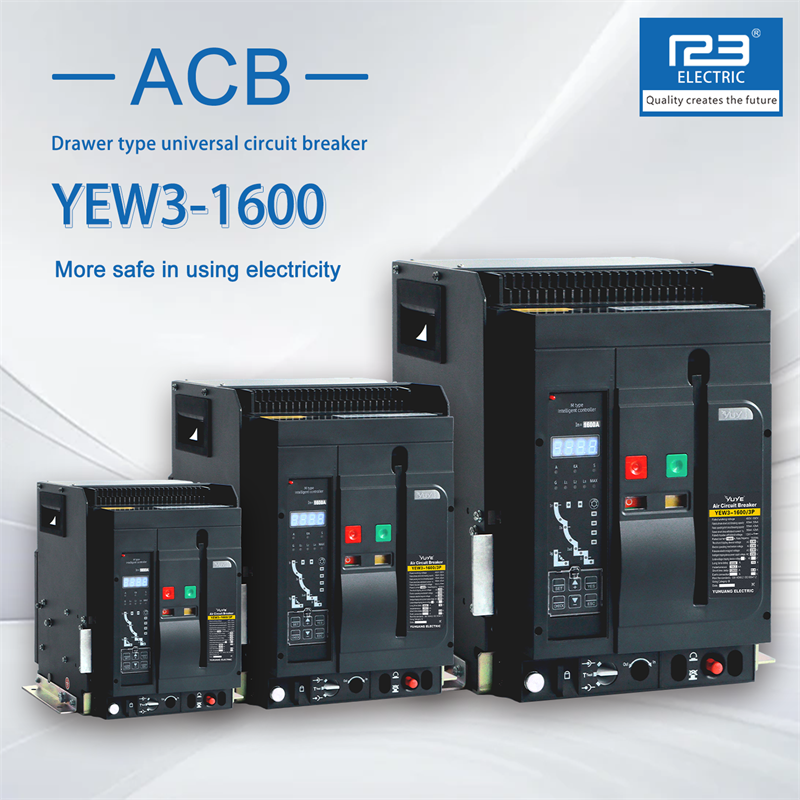

Air Circuit Breaker YEW1-2000~6300 Air Circuit Breaker YEW3-1600

Air Circuit Breaker YEW3-1600 Load isolation switch YGL-63~3150

Load isolation switch YGL-63~3150 Load Isolation Switch YGL2-63~3150

Load Isolation Switch YGL2-63~3150 Manual Changeover Switch YGL-100~630Z1A

Manual Changeover Switch YGL-100~630Z1A Manual Changeover Switch YGLZ1-100~3150

Manual Changeover Switch YGLZ1-100~3150 YECPS2-45~125 LCD

YECPS2-45~125 LCD YECPS-45~125 Digital

YECPS-45~125 Digital CNC Milling/Turning-OEM

CNC Milling/Turning-OEM DC relay MDC-300M

DC relay MDC-300M DC Isolation Switch YEGL3D-630

DC Isolation Switch YEGL3D-630