In the field of electrical engineering, the terms “high voltage” and “low voltage” are often encountered, but they often lead to confusion for those unfamiliar with the field. Understanding the differences between these two categories is critical to the safety and functionality of electrical systems. This blog aims to clarify the differences between high voltage and low voltage, exploring their definitions, applications, safety considerations and regulatory standards.

The definitions of high voltage and low voltage are mainly determined by the environment in which they are used. Generally speaking, low voltage refers to electrical systems with alternating current (AC) voltages below 1,000 volts (1 kV) and direct current (DC) voltages below 1,500 volts (1.5 kV). Common examples of low voltage applications include residential wiring, lighting systems, and small appliances. In contrast, high voltage generally refers to systems operating at voltages above these thresholds. High voltage systems are commonly used in power transmission and distribution networks where electricity must be transported over long distances with minimal energy loss. The distinction is not just academic; It has a significant impact on the design, operation and maintenance of electrical systems.

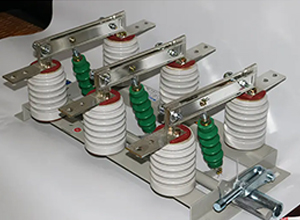

The application of high and low pressure systems further highlights their differences. Low voltage systems are primarily used in residential and commercial settings to power everyday appliances and lighting. These systems are designed to be easy to use and safe, often incorporating protection measures such as circuit breakers and fuses to prevent overloading. High-voltage systems, on the other hand, are critical for efficient transmission of electricity from power plants to substations and ultimately to consumers. These systems require specialized equipment such as transformers and insulators to manage the increased electrical stress and ensure safe operation. High-pressure system infrastructure is more complex and expensive, reflecting the need for advanced technology and strict safety protocols.

Safety considerations are crucial when discussing high and low pressure systems. Low-voltage systems, while generally safer for everyday use, still pose risks, especially if they are not installed or maintained properly. If safety standards are not followed, electric shock, short circuit, and fire hazards may occur. However, high-pressure systems pose far greater risks. The possibility of serious electric shock, arc flash accidents, and equipment failure requires strict safety measures. Personnel working with high voltage systems must receive specialized training and adhere to strict safety protocols, including the use of personal protective equipment (PPE) and lockout/tagout procedures. Regulatory agencies such as the Occupational Safety and Health Administration (OSHA) and the National Electrical Code (NEC) provide guidance for ensuring the safe operation of high- and low-voltage systems.

Regulatory standards play a vital role in defining and managing high- and low-voltage systems. Various international and national standards exist to classify voltage levels and establish safety requirements. For example, the International Electrotechnical Commission (IEC) provides guidelines for classifying voltages into different categories, affecting how electrical systems around the world are designed and operated. Compliance with these standards is critical to ensuring the safety and reliability of electrical systems. In many jurisdictions, electrical installations must be inspected and certified to meet these regulatory requirements, further emphasizing the importance of understanding the difference between high and low voltage.

The distinction between high and low voltage in electrical systems is more than just a matter of terminology; it covers critical aspects of safety, application, and regulatory compliance. Understanding these differences is critical for anyone involved in the design, installation, or maintenance of electrical systems. As technology continues to evolve, the importance of adhering to safety standards and regulations will only increase, so professionals and laypeople alike must master the nuances of high and low pressure systems. By deepening our understanding of these concepts, we can improve the safety, efficiency, and reliability of our power infrastructure.

PC ATS YECT1-2000G

PC ATS YECT1-2000G PC ATS YES2-63~250GN1

PC ATS YES2-63~250GN1 Solenoid-type ATS YES1-32~125N

Solenoid-type ATS YES1-32~125N Solenoid-type ATS YES1-250~630N/NT

Solenoid-type ATS YES1-250~630N/NT Solenoid-type ATS YES1-32~125NA

Solenoid-type ATS YES1-32~125NA Solenoid-type ATS YES1-63~630SN

Solenoid-type ATS YES1-63~630SN Solenoid-type ATS YES1-1250~4000SN

Solenoid-type ATS YES1-1250~4000SN Solenoid-type ATS YES1-250~630NA/NAT

Solenoid-type ATS YES1-250~630NA/NAT Solenoid-type ATS YES1-63NJT

Solenoid-type ATS YES1-63NJT PC ATS YES1-100~1600GN1/GN/GNF

PC ATS YES1-100~1600GN1/GN/GNF PC ATS YES1-2000~3200GN/GNF

PC ATS YES1-2000~3200GN/GNF PC ATS YES1-100~3200GA1/GA

PC ATS YES1-100~3200GA1/GA Solenoid-type ATS YES1-63~630SA

Solenoid-type ATS YES1-63~630SA Solenoid-type ATS YES1-63~630L/LA

Solenoid-type ATS YES1-63~630L/LA Solenoid-type ATS YES1-63~630LA3

Solenoid-type ATS YES1-63~630LA3 Solenoid-type ATS YES1-63MA

Solenoid-type ATS YES1-63MA PC ATS YES1-630~1600M

PC ATS YES1-630~1600M PC ATS YES1-3200Q

PC ATS YES1-3200Q Solenoid-type ATS YES1-4000~6300Q

Solenoid-type ATS YES1-4000~6300Q CB ATS YEQ1-63J

CB ATS YEQ1-63J CB ATS YEQ2Y-63

CB ATS YEQ2Y-63 CB ATS YEQ3-63W1

CB ATS YEQ3-63W1 CB ATS YEQ3-125~630W1

CB ATS YEQ3-125~630W1 ATS controller Y-700

ATS controller Y-700 ATS Controller Y-700N

ATS Controller Y-700N ATS Controller Y-701B

ATS Controller Y-701B ATS Controller Y-703N

ATS Controller Y-703N ATS Controller Y-800

ATS Controller Y-800 ATS Controller W2/W3 Series

ATS Controller W2/W3 Series ATS switch Cabinet floor-to-ceiling

ATS switch Cabinet floor-to-ceiling ATS switch cabinet

ATS switch cabinet JXF-225A power Cbinet

JXF-225A power Cbinet JXF-800A power Cbinet

JXF-800A power Cbinet YEM3-125~800 Plastic Shell Type MCCB

YEM3-125~800 Plastic Shell Type MCCB YEM3L-125~630 Leakage Type MCCB

YEM3L-125~630 Leakage Type MCCB YEM3Z-125~800 Adjustable Type MCCB

YEM3Z-125~800 Adjustable Type MCCB YEM1-63~1250 Plastic Shell Type MCCB

YEM1-63~1250 Plastic Shell Type MCCB YEM1E-100~800 Electronic Type MCCB

YEM1E-100~800 Electronic Type MCCB YEM1L-100~630 Leakage Type MCCB

YEM1L-100~630 Leakage Type MCCB Miniature circuit breaker YEMA2-6~100

Miniature circuit breaker YEMA2-6~100 Miniature circuit breaker YEB1-3~63

Miniature circuit breaker YEB1-3~63 Miniature circuit breaker YEB1LE-3~63

Miniature circuit breaker YEB1LE-3~63 Miniature circuit breaker YEPN-3~32

Miniature circuit breaker YEPN-3~32 Miniature circuit breaker YEPNLE-3~32

Miniature circuit breaker YEPNLE-3~32 Miniature circuit breaker YENC-63~125

Miniature circuit breaker YENC-63~125 Air Circuit Breaker YEW1-2000~6300

Air Circuit Breaker YEW1-2000~6300 Air Circuit Breaker YEW3-1600

Air Circuit Breaker YEW3-1600 Load isolation switch YGL-63~3150

Load isolation switch YGL-63~3150 Load Isolation Switch YGL2-63~3150

Load Isolation Switch YGL2-63~3150 Manual Changeover Switch YGL-100~630Z1A

Manual Changeover Switch YGL-100~630Z1A Manual Changeover Switch YGLZ1-100~3150

Manual Changeover Switch YGLZ1-100~3150 YECPS2-45~125 LCD

YECPS2-45~125 LCD YECPS-45~125 Digital

YECPS-45~125 Digital CNC Milling/Turning-OEM

CNC Milling/Turning-OEM DC relay MDC-300M

DC relay MDC-300M DC Isolation Switch YEGL3D-630

DC Isolation Switch YEGL3D-630