The automatic transfer switch (ATS) is a key device in dual power supply systems, mainly used to automatically switch between the main power supply and the backup power supply to ensure continuous power supply to critical loads. Standard and scientific installation not only relates to the safe operation of the equipment itself but also directly affects the stability of the entire power supply system and the convenience of later maintenance. This article provides a detailed explanation of the key points to note during the installation process, with special attention to Automatic Changeover Switch Wiring practices.

I. Environmental and Site Preparation Requirements Before Installation

Before installing the ATS, a comprehensive inspection of the installation environment must be carried out. The installation site should be kept dry, clean, and well ventilated. The environmental temperature and humidity should comply with the provisions of the equipment technical documents to avoid damage caused by high temperature, high humidity, or condensation.

The distribution room should have basic dust-proof and moisture-proof measures, with a flat floor and no water accumulation. Sufficient installation space and maintenance channels should be reserved to ensure convenient operation during later maintenance and component replacement. For places prone to vibration or electromagnetic interference, shock absorption and shielding measures should be taken, which also helps improve the safety of Automatic Changeover Switch Wiring.

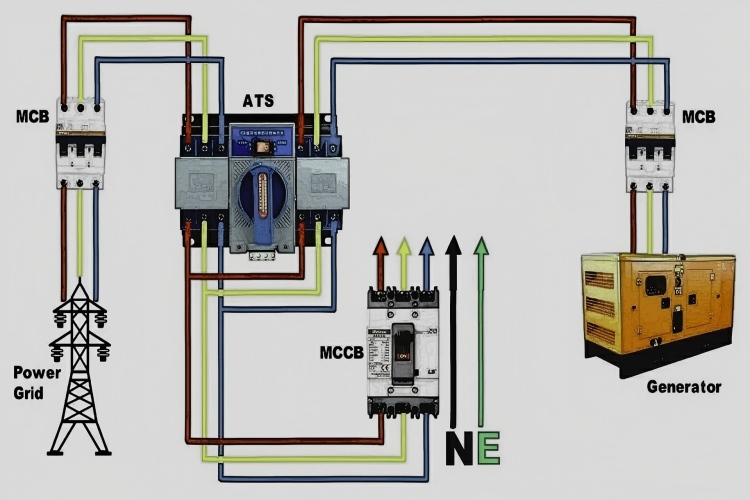

II. Wiring Specifications for Main Power Supply and Standby Power Supply

The wiring of the main power supply and backup power supply must be strictly carried out in accordance with design drawings and product manuals. The rated voltage, frequency, and capacity of the two power supplies should be consistent to ensure reliable switching performance.

Before wiring, it is essential to carefully check the phase sequence to ensure that the phase sequence of the main and backup power sources is consistent, preventing equipment malfunction or load damage. It is strictly forbidden to operate the two power sources in parallel, and mechanical and electrical interlock devices must be effective and reliable. Proper Automatic Changeover Switch Wiring ensures that both power sources remain electrically isolated and safely controlled.

Incoming and outgoing cables should be reasonably selected based on load capacity, and clear, durable line markings should be made to facilitate later maintenance and troubleshooting of Automatic Changeover Switch Wiring systems.

III. Key Points for Safety of Equipment Fixation and Installation Structures

The ATS equipment should be installed on a solid and flat foundation or cabinet to ensure uniform force distribution and prevent tilting or shaking. Installation brackets, rails, or cabinet structures should have sufficient mechanical strength to bear the equipment’s own weight and operational mechanical stress.

In areas prone to earthquakes or high-vibration environments, reinforcement measures should be taken in accordance with relevant seismic standards. The equipment casing should be reliably grounded and equipotential bonding should be properly implemented to ensure current can be safely discharged in case of faults, supporting the overall safety of Automatic Changeover Switch Wiring and system operation.

IV. Installation Precautions for Control Lines and Communication Interfaces

The control circuits should be laid separately from the main power cables to prevent electromagnetic interference from affecting control signals. A reasonable distance should be maintained between strong current and weak current lines, and when necessary, metal conduits or shielded cables should be used for protection.

ATS devices with communication functions (such as RS485 and Modbus interfaces) should be wired strictly in accordance with interface specifications, paying attention to positive and negative polarity and terminal resistor configuration. Communication cables should use shielded twisted-pair wires and be properly grounded to prevent signal interference and ensure stable Automatic Changeover Switch Wiring performance.

V. Key Points for Debugging and Safety Inspection After Installation Completion

Before the system is officially powered on, a comprehensive safety check should be conducted. First, perform an insulation resistance test to confirm that the insulation performance of the main circuit and control circuit meets the requirements.

Next, check whether the voltage, frequency, and phase sequences of the main and backup power supplies are normal. Test the automatic switching function by manually simulating a power failure to confirm correct switching logic and reliable operation. The reliability of manual/automatic switching should also be verified, ensuring that the Automatic Changeover Switch Wiring is functioning as designed.

Finally, check that safety warning signs and operation instruction labels are complete and clear to support standardized and safe operation.

Conclusion

Proper installation is the foundation for ensuring the long-term safe and stable operation of an ATS system. By strictly adhering to environmental preparation, wiring standards, equipment fixation, control circuit laying, and commissioning checks, the overall reliability and safety of the system can be significantly enhanced. Well-executed Automatic Changeover Switch Wiring plays a vital role in providing continuous and stable power for critical loads.

PC ATS YECT1-2000G

PC ATS YECT1-2000G PC ATS YES2-63~250GN1

PC ATS YES2-63~250GN1 Solenoid-type ATS YES1-32~125N

Solenoid-type ATS YES1-32~125N Solenoid-type ATS YES1-250~630N/NT

Solenoid-type ATS YES1-250~630N/NT Solenoid-type ATS YES1-32~125NA

Solenoid-type ATS YES1-32~125NA Solenoid-type ATS YES1-63~630SN

Solenoid-type ATS YES1-63~630SN Solenoid-type ATS YES1-1250~4000SN

Solenoid-type ATS YES1-1250~4000SN Solenoid-type ATS YES1-250~630NA/NAT

Solenoid-type ATS YES1-250~630NA/NAT Solenoid-type ATS YES1-63NJT

Solenoid-type ATS YES1-63NJT PC ATS YES1-100~1600GN1/GN/GNF

PC ATS YES1-100~1600GN1/GN/GNF PC ATS YES1-2000~3200GN/GNF

PC ATS YES1-2000~3200GN/GNF PC ATS YES1-100~3200GA1/GA

PC ATS YES1-100~3200GA1/GA Solenoid-type ATS YES1-63~630SA

Solenoid-type ATS YES1-63~630SA Solenoid-type ATS YES1-63~630L/LA

Solenoid-type ATS YES1-63~630L/LA Solenoid-type ATS YES1-63~630LA3

Solenoid-type ATS YES1-63~630LA3 Solenoid-type ATS YES1-63MA

Solenoid-type ATS YES1-63MA PC ATS YES1-630~1600M

PC ATS YES1-630~1600M PC ATS YES1-3200Q

PC ATS YES1-3200Q Solenoid-type ATS YES1-4000~6300Q

Solenoid-type ATS YES1-4000~6300Q CB ATS YEQ1-63J

CB ATS YEQ1-63J CB ATS YEQ2Y-63

CB ATS YEQ2Y-63 CB ATS YEQ3-63W1

CB ATS YEQ3-63W1 CB ATS YEQ3-125~630W1

CB ATS YEQ3-125~630W1 ATS controller Y-700

ATS controller Y-700 ATS Controller Y-700N

ATS Controller Y-700N ATS Controller Y-701B

ATS Controller Y-701B ATS Controller Y-703N

ATS Controller Y-703N ATS Controller Y-800

ATS Controller Y-800 ATS Controller W2/W3 Series

ATS Controller W2/W3 Series ATS switch Cabinet floor-to-ceiling

ATS switch Cabinet floor-to-ceiling ATS switch cabinet

ATS switch cabinet JXF-225A power Cbinet

JXF-225A power Cbinet JXF-800A power Cbinet

JXF-800A power Cbinet YEM3-125~800 Plastic Shell Type MCCB

YEM3-125~800 Plastic Shell Type MCCB YEM3L-125~630 Leakage Type MCCB

YEM3L-125~630 Leakage Type MCCB YEM3Z-125~800 Adjustable Type MCCB

YEM3Z-125~800 Adjustable Type MCCB YEM1-63~1250 Plastic Shell Type MCCB

YEM1-63~1250 Plastic Shell Type MCCB YEM1E-100~800 Electronic Type MCCB

YEM1E-100~800 Electronic Type MCCB YEM1L-100~630 Leakage Type MCCB

YEM1L-100~630 Leakage Type MCCB Miniature circuit breaker YEMA2-6~100

Miniature circuit breaker YEMA2-6~100 Miniature circuit breaker YEB1-3~63

Miniature circuit breaker YEB1-3~63 Miniature circuit breaker YEB1LE-3~63

Miniature circuit breaker YEB1LE-3~63 Miniature circuit breaker YEPN-3~32

Miniature circuit breaker YEPN-3~32 Miniature circuit breaker YEPNLE-3~32

Miniature circuit breaker YEPNLE-3~32 Miniature circuit breaker YENC-63~125

Miniature circuit breaker YENC-63~125 Air Circuit Breaker YEW1-2000~6300

Air Circuit Breaker YEW1-2000~6300 Air Circuit Breaker YEW3-1600

Air Circuit Breaker YEW3-1600 Load isolation switch YGL-63~3150

Load isolation switch YGL-63~3150 Load Isolation Switch YGL2-63~3150

Load Isolation Switch YGL2-63~3150 Manual Changeover Switch YGL-100~630Z1A

Manual Changeover Switch YGL-100~630Z1A Manual Changeover Switch YGLZ1-100~3150

Manual Changeover Switch YGLZ1-100~3150 YECPS2-45~125 LCD

YECPS2-45~125 LCD YECPS-45~125 Digital

YECPS-45~125 Digital CNC Milling/Turning-OEM

CNC Milling/Turning-OEM DC relay MDC-300M

DC relay MDC-300M DC Isolation Switch YEGL3D-630

DC Isolation Switch YEGL3D-630